NUTRITIONAL VALUE, APPLICATIONS, CHALLENGES, AND PROSPECTS OF SHRIMP PROCESSING WASTE IN AQUACULTURE FEED

The global shrimp processing industry generates substantial amounts of solid waste (head, abdominal exoskeleton, and tail), with a considerable part currently being disposed of in landfills. It holds significant potential as an alternative ingredient in aquaculture feed due to its relatively high crude protein content, balanced amino acid profile, and presence of bioactive compounds. However, one of the main challenges with shrimp processing waste is its rapid spoilage. Consequently, shrimp solid processing waste must undergo further refinement to produce shrimp-derived products suitable as aquaculture feed ingredients, such as meal, hydrolysate, or silage. This literature review describes the nutritional value, applications, challenges, and prospects of these shrimp-derived products in aquaculture feed.

1 Introduction

The total global aquatic animal production through fisheries and aquaculture reached 178 million metric tonnes in 2020, with projections indicating sustained growth driven by rising incomes, population growth, urbanization, and changing dietary preferences (FAO, 2020). As landings by capture fisheries have remained stable for several decades, these increasing demands can only be met by growth in the aquaculture sector. Most of this growth is realized through a global increase in fed-based aquaculture, driven by species such as African catfish (Clarias gariepinus), Atlantic salmon (Salmo salar), common carp (Cyprinus carpio), European seabass (Dicentrarchus labrax), giant tiger prawn (Penaeus monodon), Nile tilapia (Oreochromis niloticus), rainbow trout (Oncorhynchus mykiss), red seabream (Pagrus major), and whiteleg shrimp (Litopenaeus vannamei) (FAO, 2020). As fed-based aquaculture requires the provision of feed, further increases in feed raw material demands can be expected over the coming decades. Fishmeal was traditionally used as the main protein source in aquafeed due to its balanced amino acid profile, high palatability, and high digestibility ( Zhou et al., 2004). However, fishmeal is a competitive commodity with a high price (~1730 USD per metric ton, February 2024) (Indexmundi,2004). The most commonly used alternative ingredient for fishmeal worldwide is soybean meal due to its relatively similar amino acid profile, worldwide availability, and lower price (~460 USD per metric ton, February 2024) (Indexmundi, 2004), while in some instances, other soybean products are used, such as soybean isolate or soybean concentrate. Nonetheless, the dietary inclusion of unrefined soybean meal in aquafeed can pose challenges related to nutrient digestibility, palatability, and health, depending on the aquaculture species (Storebakken et al., 1998; Uran et al., 2007). Furthermore, certain sources of fishmeal and soybean meal may be associated with sustainability concerns, including overfishing and deforestation, respectively (FAO, 2022; Alexandratos and Bruinsma , 2022). These challenges, together with the expansion of the aquaculture sector and increasing emphasis on the circular economy, have propelled research to identify alternative protein sources for aquafeed including single-cell proteins, microalgae, insects, and shrimp processing waste.

Shrimp processing waste, in this review encompassing waste from both shrimps and prawns due to the lack of a concise definition of either term, is of interest for aquafeed applications because of its relatively high crude protein content, balanced amino acid profile, and presence of bioactive compounds (Eggink et al., 2022; Kandra et al., 2012). During shrimp processing, parts considered “inedible” for human consumption can be removed (head, abdominal exoskeleton, and tail), which are subsequently regarded as solid waste. This solid processing waste can make up 35%–65% of the total shrimp production weight, depending on, amongst others, the shrimp species and processing efficiency (Saini et al., 2020; Liu et al., 2021).

In 2020, the combined supply of shrimp provided by fisheries and aquaculture reached approximately 10 million metric tonnes (wet weight), resulting in roughly 3.5–6.5 million metric tonnes of shrimp solid processing waste (FAO, 2022). Only a small fraction of global shrimp processing waste is further processed for other industries, whereas most is disposed of in landfills due to its perishable nature (Kandra et al., 2012). The disposal of shrimp processing waste is not only a loss of valuable nutrients but is also associated with adverse environmental impacts including water pollution, habitat degradation, and greenhouse gas emissions (Kandra et al., 2012). More efficient utilization of shrimp processing waste can aid in enhancing the sustainable and economic viability of shrimp processing industries while simultaneously contributing to the circular economy concept.

In recent decades, shrimp processing waste has been investigated as a source of bioactive compounds and as a feed ingredient. Numerous in-depth literature reviews have described biotechnological processes for obtaining bioactive compounds from shrimp processing waste, including long-chain polyunsaturated fatty acids, polysaccharides, and carotenoids (Nirmal et al., 2020; Kandra et al., 2012; Mao et al., 2016 and Wani et al., 2023). These bioactive compounds have been shown to have, amongst others, antioxidant, antimicrobial, and/or anti-inflammatory properties, finding applications in various industries including cosmetics, pharmaceuticals, and agriculture (Cahu et al., 2017; Nirmal et al., 2024). Given their wide range of applications, considerable efforts are being made towards overcoming previous hurdles by improving extraction efficiency, enhancing cost-effectiveness, and employing green extraction technologies to reduce their environmental impact (Nirmal et al., 2024). Despite extensive research on the purification and applications of these bioactive compounds from shrimp processing waste, the utilization of shrimp-derived products as a replacement for current protein sources in aquafeed remains underexplored. This literature review therefore evaluates the nutritional composition of shrimp-derived products (meal, hydrolysate, and silage) and assesses their applications as alternative ingredients in formulated aquaculture feed. Furthermore, the current challenges associated with shrimp-derived products in aquafeed are discussed, as well as potential strategies to overcome them.

2 Shrimp-Derived Products

Of the total global shrimp supply of 10 million metric tonnes (wet weight) in 2020, approximately 70% was produced by aquaculture (FAO, 2022). Over the past decade, shrimp aquaculture has been almost completely reliant on one shrimp species which is the whiteleg shrimp (L. vannamei), accounting for roughly 6.8 million metric tonnes (wet weight) in 2022 (FAO, 2024). The majority of shrimp fisheries and aquaculture activities are concentrated in Asia and, to a lesser extent, South America (FAO, 2022). For both continents, shrimp are often processed immediately after collection, which is driven by the cost-effectiveness of labor in these locations (Hannan et al., 2022). The processing location is also dependent on the shrimp source; when obtained through fisheries, initial processing may occur at sea (provided the fleet is equipped with onboard processing capacity), whereas when obtained through aquaculture, processing typically occurs on land.

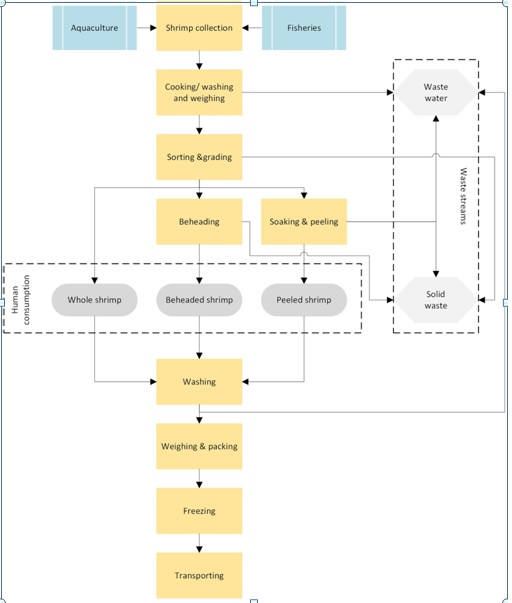

Initial processing involves washing, cooking, weighing, sorting, and grading, as illustrated in Figure 1. Immediately after collection, shrimp are cooked or washed to ensure high product quality and, in the case of marine shrimp species, to remove salt residues. Additional washing steps are required after further processing steps, which remove chemicals or other impurities (Nirmal et al., 2020). Both the cooking and washing steps in shrimp processing result in the generation of wastewater, estimated at approximately 15 m3 per metric ton of raw shrimp (Anh et al., 2011). The highly diluted nutrient content in processing wastewater currently renders it economically inviable as an aquafeed ingredient, as it would require extensive processing. Processing wastewater is therefore not further discussed in this literature review.

Fig 1: Flow chart illustrating critical steps involved in producing final shrimp products for human consumption from freshly collected shrimp by aquaculture or fisheries (modified version based on (Nirmal et al., 2020). Shrimp sources are indicated in blue, processing steps in yellow, products for human consumption in dark gray, and waste streams in light gray.

After cooking and washing, shrimp are sorted and graded according to their size and quality. Shrimp that do not meet the size specifications for human consumption are commonly repurposed, for example as a pet food ingredient due to quality and price considerations. Graded shrimp, deemed suitable for human consumption, are then categorized according to the desired final product being (1) whole shrimp, (2) beheaded shrimp, or (3) peeled shrimp (Nirmal et al., 2020). All three final products undergo subsequent processing steps, including washing, weighing, packing, freezing, and transporting, before being sold to consumers (Figure 1).

Substantial amounts of solid processing waste are generated at the processing site when beheaded or peeled shrimp are the final products. For beheaded shrimp, the head is removed, leaving the rest of the exoskeleton attached. For peeled shrimp, the head, abdominal exoskeleton, and tail are removed (Figure 2). The proportion of total solid waste (head, abdominal exoskeleton, and tail) relative to the shrimp weight typically ranges from 35% to 65% (Table 1), of which the head makes up the predominant fraction of the total solid waste weight, ranging from 65% to 85% (Heu et al., 2003; Liu et al., 2021).

Fig 2: Visual representation of three commonly separated fractions during shrimp processing: Head (including antennae, carapace, eyes, pereopods, rostrum), abdominal exoskeleton (including abdominal segments, pleopods), and tail (including telson, uropods) (modified version based on a previous study (Tavares, 2002).

The relative proportion of total solid waste is dependent on, amongst others, the shrimp species and processing efficiency. Of the described shrimp species in the literature, L. vannamei had the lowest relative fraction of solid processing waste (35.6%–44.1%) and Macrobrachium rosenbergii had the highest (62.5%) (Table 1). Dissimilarities between species may be related to differences in size and morphology whereas differences within the same shrimp species may be attributed to differences in size and peeling efficiencies across studies. Notably, manual shrimp peeling is generally known to be more accurate in separating the meat part from the exoskeleton part, therefore yielding a lower fraction of solid processing waste (Tavares, 2002).

To be able to utilize shrimp solid processing waste in aquafeed, additional processing is necessary to change its physicochemical properties, enhance its nutritional quality, and prevent spoilage (Fricke et al., 2022). Depending on the methods applied, various shrimp-derived products can be produced including shrimp meal, hydrolysate, and silage. The processing methods for each of these products are described in more detail below.

2.1 Shrimp Meal

The term “shrimp meal” is often used in the literature to describe either shrimp head meal or shrimp waste meal (containing head, abdominal exoskeleton, and tail). Regardless of the type of meal, the following processes can be applied to produce shrimp meal: washing, drying, grinding/milling, and sieving (Figure 3). A washing step is often performed to remove impurities present from previous processing steps (Nirmal et al., 2020). Subsequently, drying is required to produce a meal with a relatively low moisture content to extend its shelf life and enhance formulation for aquafeed purposes. Solar, freeze, and oven drying are examples of drying methods applied in the industryv( Das and Mishra, 2023). Afterwards, grinding/milling, possibly followed by sieving, can be performed to obtain a uniform particle size, which supports the formation of a high-quality feed pellet.

Fig 3: Flow chart illustrating the processing steps involved in shrimp meal production from shrimp solid processing waste (based on the in-text description in previous studies ( Sangkaew and Koh, 2021; Fricke et al., 2023).

2.2 Shrimp Hydrolysate

Shrimp hydrolysate is obtained by hydrolyzing shrimp solid processing waste, where protein-bound amino acids are solubilized in water. Steps involved in shrimp hydrolysate production include washing, grinding/milling, hydrolysis, filtration, and centrifugation (Figure 4). Prior to hydrolysis, a washing or grinding/milling step can be included to remove impurities and increase the surface area for hydrolysis, respectively. Afterwards, chemical or enzymatic hydrolysis can be applied to break down proteins into shorter peptides and amino acids (Fricke et al., 2023). Chemical hydrolysis refers to the use of either highly acidic or alkaline solutions, usually in combination with high pressure and/or high temperature. Due to the large volumes of chemical waste produced during chemical hydrolysis, recent attention has shifted towards enzymatic hydrolysis (Ambigaipalan and Shahidi, 2017). Enzymatic hydrolysis relies on proteolytic enzymes (e.g., chymotrypsin, papain, and subtilisin) to break down proteins ( Wisuthiphaet et al., 2015; Mizani et al, 2005). As proteolytic enzymes are highly specific, enzymatic hydrolysis allows greater control over the quality of the final products (Niko et al., 2023), but, unlike chemical hydrolysis, does not result in the breakdown of chitin unless chitinolytic enzymes are added (Rustad et al., 2011). Following hydrolysis, filtration is performed, resulting in a solid and a liquid fraction. The liquid fraction is further processed by centrifugation, to yield the hydrolysate whereas the precipitate is discarded (De Holanda and Netto, 2006). To be able to include the hydrolysate in aquafeed, an additional concentration step might be needed to reduce the moisture content.

Fig 4: Flow chart illustrating the processing steps involved in shrimp hydrolysate production from shrimp solid processing waste (modified version based on previous studies (Mizani et al., 2005; Gildberg and Stenberg, 2001; Synowiecki and Al-Khateeb, 2000).

2.3 Shrimp Silage

Ensiling is a traditional method to prolong the shelf life of shrimp solid processing waste and, in certain cases, improve its nutritional value. To produce shrimp silage, the following steps are required: washing, grinding/milling, addition of acid/fermentable carbohydrates/lactic acid bacteria, mixing, liquefaction, and centrifugation (Figure 5). Washing and grinding/milling are optional steps and their functions are similar to what has been described previously. To produce silage, the pH needs to be below 4.5, which can be achieved either by the addition of acids (acid silage) or through anaerobic fermentation using lactic acid bacteria (fermented silage) (Synowiecki and Al-Khateeb, 2000 ; Evers and Carroll, 1996). In the latter, lactic acid bacteria can convert fermentable carbohydrates into lactic acid. As shrimp solid processing waste contains a low amount of fermentable carbohydrates, supplementary fermentable carbohydrate sources (e.g., molasses, tapioca, etc.) are often added to the mixture, sometimes in combination with a starter culture of lactic acid bacteria (Guillou et al., 1995). Acids originating either from acid addition or lactic acid bacteria will reduce the pH, resulting in an inhibition of undesirable microorganisms and preservation of the nutritional quality. To ensure homogenous ensiling, it is necessary to mix the raw materials with acids, fermentable sugars, and/or lactic acid bacteria. During liquefaction, different processes occur including the production of lipophilic compounds, denaturation of proteins, and solubilization of minerals ( Hertrampf and Piedad-Pasc, 2000). Afterwards, the liquid and solid components can be separated by centrifugation, resulting in a solid fraction primarily composed of chitin and insoluble minerals, and a liquid fraction containing proteins, lipids, and carotenoids (Evers and Carroll,1996). Subsequently, the liquid fraction can be dried to produce a concentrate, better suited for aquafeed purposes.

3 Nutritional Composition

Shrimp-derived products consist, on a dry matter (DM) basis, of 33%–74% crude protein, 10%–28% ash, 1%–16% chitin, and 4%–8% crude lipid. Several bioactive compounds can be found in shrimp-derived products, including amino acids, long-chain polyunsaturated fatty acids, polysaccharides, minerals, and carotenoids. The contents of these nutrients in the different shrimp-derived products are described below in more detail. For further information regarding the extraction and specific bioactivities of each compound, we refer to previously published reviews (Nirmal et al., 2020; Cabanillas-Bojórquez et al., 2021).

3.1 Crude Protein and Amino Acids

To replace conventional protein sources in aquafeed, it is essential to consider their protein content and amino acid profile. Fishmeal and soybean meal contain approximately 65%–75% and 45%–55% crude protein on a DM basis, respectively, while shrimp-derived products contain 33%–74% crude protein on a DM basis. Among the shrimp-derived products presented, shrimp hydrolysate and shrimp silage have the highest and lowest relative crude protein content, respectively. Previous research indicates that ensiling shrimp solid processing waste can result in a reduction of its relative crude protein content (Guillou et al., 1995; Rossi et al., 2024). The decrease in crude protein content may be caused by, amongst others, non-protein nitrogen losses, amino acid degradation, and the relative dilution of crude protein by the addition of acids, fermentable carbohydrates, and/or lactic acid bacteria. Ensiling not only affects the crude protein content but also the type of nitrogen sources present, as it can result in the conversion of protein into non-protein nitrogen sources such as ammonia, potentially reducing its nutritional value for aquafeed purposes ( Franco-Zavaleta et al., 2010). However, commonly used nitrogen determination methods such as Kjeldahl and Dumas, used to estimate crude protein content, cannot differentiate between sources of protein nitrogen and non-protein nitrogen (Fagbenro, 1996). To identify which compounds crude protein is converted into during the ensiling of shrimp solid processing waste, additional quantification of individual nitrogen-containing compounds is needed.

To assess shrimp-derived products as a dietary protein source, it is particularly important to evaluate their amino acid profile and the ratio of essential to nonessential amino acids. Of the shrimp-derived products, shrimp hydrolysate has the highest relative contents of both essential and nonessential amino acids—for most amino acids, these contents are higher than fishmeal. The relative amino acid profiles of shrimp solid processing waste and shrimp meal are generally inferior compared to fishmeal and soybean meal. That said, the methionine contents, one of the main limiting amino acids in aquafeed, might be slightly higher in these shrimp-derived products compared to soybean meal. Unfortunately, the number of studies investigating the amino acid profile in shrimp silage is limited. From the quantified amino acids, it appears that the amino acid contents are lower in silage than in the other shrimp-derived products, as well as both fishmeal and soybean meal. However, more studies are required to confirm these results.

The ratio between essential and nonessential amino acids was calculated for the other shrimp-derived products and appeared to be balanced, ranging from 1:1.0 to 1:1.2. These ratios fall within the range previous studies have demonstrated to be optimal for various fish species being 1:1.0–1:1.3. Within this optimal range, nitrogen retention is maximized while nitrogen excretion is minimized. When considering both the amino acid profile and the ratio of essential to nonessential amino acids, shrimp hydrolysate has the highest protein quality of the investigated shrimp-derived products.

3.2 Crude Lipid and Lipid Classes

The crude lipid content in shrimp-derived products (4%–8% DM) is slightly lower than that in fishmeal (~9% DM) but higher than in soybean meal (~2% DM). Only a limited number of studies have investigated the fatty acid profile of shrimp-derived products, possibly because they are primarily considered protein sources in aquafeed formulation. Fatty acid profiles of shrimp meal, shrimp silage, and shrimp processing waste are compared to fishmeal and soybean meal, as shown in Table 4. Notably, Table 4 does not contain the fatty acid profile of shrimp hydrolysate as, to our knowledge, no studies have investigated this.

3.3 Polysaccharides

The primary polysaccharide found in shrimp-derived products is chitin, a polymer composed of β-1,4-N-acetyl-D-glucosamine subunits, that plays a major role in the structure of the crustacean exoskeleton. In the crustacean exoskeleton, chitin forms sclerotized complexes with minerals and proteins, contributing to its rigid structure. Chitin contents in shrimp-derived products vary widely, ranging from 1% to 16% DM, with the lowest contents present in shrimp hydrolysate and the highest contents in shrimp meal. Extreme pH conditions, such as during hydrolysis and ensiling, can compromise the integrity of not only protein but also chitin, breaking down chitin into its derivatives. Additionally, certain treatment conditions, such as high temperatures, can further accelerate the degradation of chitin.

3.4 Pigments and Minerals

Shrimp-derived products contain various pigments including astaxanthin and β-carotene, which belong to the group of carotenoids. Carotenoids are produced by phytoplankton and bacteria, and are accumulated throughout the food chain, eventually ending up in crustaceans, fish, and birds. Astaxanthin and β-carotene are red and orange carotenoids, respectively, and are known for their colouring properties as well as their antioxidant properties. Previously reported total carotenoid contents in shrimp solid processing waste ranged from 47 to 332 mg/kg DM, with astaxanthin being the primary carotenoid present. The carotenoid contents can greatly vary depending on the shrimp’s dietary intake as well as the processing techniques applied.

The most abundant minerals found in shrimp-derived products are calcium and phosphorus. These minerals play a vital role in the exoskeleton formation of crustaceans . Mineral salts, predominantly calcium carbonate and calcium phosphate, are embedded within the chitin matrix together with proteins, adding strength and stiffness to the exoskeleton. Shrimp solid processing waste and shrimp meal (both 8%–9% DM) as well as shrimp silage (~6% DM) contain relatively high contents of calcium compared to fishmeal (~3% DM) and soybean meal (~0.3% DM). The total phosphorus content is lower in all shrimp-derived products (0.1%–1.7% DM) compared to fishmeal (~2.4% DM) and in line with soybean meal (~0.7% DM). It should be noted that the total phosphorus contents depicted here include non-available phosphorus, which is phosphorus that cannot be utilized by aquaculture species.

4 Aquafeed Applications

Shrimps form part of the natural diet of several omnivorous and carnivorous aquaculture species. Consequently, a considerable number of studies have examined the feasibility of replacing fishmeal or soybean meal with shrimp-derived products in aquaculture species by investigating, amongst others, growth performance, nutrient digestibility, body composition, and health performance. In the following sections, a comprehensive overview of the literature is provided, aiming to synthesize the effects of dietary inclusion of shrimp-derived products in aquafeed.

4.1 Growth Performance

An overview of studies investigating the dietary inclusion of shrimp-derived products in aquafeed and their effects on different growth performance indicators is shown in Table 5. Due to the lack of literature available on shrimp silage as an aquaculture feed ingredient, only studies investigating shrimp hydrolysate and shrimp meal are considered. Despite some studies reporting either positive or negative effects of the dietary inclusion of shrimp-derived products on the growth performance of aquaculture species, most studies did not find any significant effects. The discrepancies in outcomes between studies can be caused by differences in, amongst other things, the investigated aquaculture species and dietary inclusion levels of shrimp-derived products. For example, the dietary replacement of fishmeal or soybean meal with shrimp-derived products seems to have a more positive effect on crustaceans than on fish, possibly because shrimp-derived products more closely align with the nutritional requirements of crustaceans. Furthermore, different dietary inclusion levels are likely to exert subsequent different effects on growth performance. Low dietary inclusion levels of shrimp meal generally did not affect growth performance in the depicted studies, whereas high dietary inclusion levels have been shown to negatively affect one or more growth performance indicators in some studies. Hardy et al. suggested that the reduction in performance may be due to the lower contents of essential amino acids in shrimp meal compared to fishmeal, which has also been described in Section 3. Additionally, shrimp-derived products contain relatively high amounts of ash (10%–28% DM). As ash has no energetic value, a high dietary ash content dilutes the energy density, which can negatively affect the amount of energy available for maintenance and growth. Lastly, shrimp-derived products contain chitin (1%–16% DM), which has previously been associated with negatively affecting the growth performance of different fish species. These effects may not be apparent at low dietary inclusion levels but may appear when a larger fraction of the protein source is replaced. Other factors could have also contributed to discrepancies between study outcomes, including the type of solid processing waste included (head, abdominal exoskeleton, and/or tail), type of processing, shrimp species, and shrimp source (wild or aquaculture). However, due to the lack of detailed information on the shrimp-derived products used, an in-depth assessment of the impact of each of these factors on growth performance could not be performed.

4.2 Nutrient Digestibility and Digestive Enzyme Activity

Although the digestibility of diets containing shrimp-derived products as replacements for conventional protein sources has only been investigated in a handful of studies (Table 6), it seems that once inclusion levels of shrimp-derived products reach 25%–30% of the total diet, there is a resultant decrease in protein and lipid digestibility. The decrease in nutrient digestibility may result from the presence of dietary chitin, as evidenced by a prior study conducted on Atlantic salmon (S. salar). That study demonstrated that crude protein digestibility significantly decreased with increasing dietary chitin contents and a similar trend was observed for lipid digestibility. High dietary levels of chitin or other indigestible materials can result in significantly reduced nutrient digestibility due to the decreased gastrointestinal transit time, limiting the time available for nutrient digestion and absorption. Additionally, chitin can physically block access of digestive enzymes to substrates like protein and lipids, reducing their digestibility. Furthermore, chitin is often in a matrix with protein, lipids, and minerals that remain unavailable when chitin is either not digested or only partially digested. Complete chitin digestibility requires several chitinolytic enzymes including endochitinases and exochitinases. Endochitinases split the chitin polymer from within, whereas exochitinases split the ends of the chitin polymer. Whether chitin can be digested is dependent on several factors, including the fish or crustacean species and their natural feeding habits.

4.3 Body Composition

As aquatic products are eventually used for human consumption, their total body composition and muscle composition are important determinants of their nutritional quality and market value. Table 7 provides an overview of currently available literature studies investigating the effects of replacing conventional protein sources with shrimp-derived products on the total body composition or muscle composition in fish and crustaceans. Most studies reported that dietary inclusion of shrimp-derived products had no significant effect on final total body composition and/or muscle tissue composition. According to these research findings, the inclusion of shrimp-derived products in the investigated organisms did not result in substantial changes in their macro nutritional quality.

4.4 Health Performance

Health performance is a central concern in aquaculture production systems. The intensification of the aquaculture sector has resulted in increased stocking densities, which can induce stress. Induced stress can impair overall health and can make aquatic animals more vulnerable to diseases. Certain components present in shrimp-derived products (e.g., chitin, astaxanthin, and peptides) have been shown to contain bioactive properties in different animal species when administered in their purified form. For example, astaxanthin has been demonstrated to possess immunomodulatory properties, enhancing survival against pathogenic challenges in various fish and crustacean species. This effect has been observed in common carp (C. carpio), kuruma shrimp (M. japonicus), northern snakehead (Channa argus), oscar (Astronotus ocellatus), and whiteleg shrimp (L. vannamei). Furthermore, chitin is known for its direct and indirect immunomodulatory properties. Chitin can have direct effects on the immune system of animals. For animals whose natural diet does not contain chitin, antigen sampling cells may recognize chitin as a pathogen-associated molecular pattern, potentially triggering an immune response. Additionally, chitin has indirect prebiotic effects by altering the gut microbiota composition and/or activity in several animal species. Furthermore, chitin and its derivative chitosan have been shown to purge potentially pathogenic bacteria from the gut by attaching these microorganisms to chitin-binding proteins in different animal species. All of these could be underlying mechanisms for the observation that chitin and chitosan have improved survival against pathogenic challenges in a variety of aquatic species including common carp (C. carpio), whiteleg shrimp (L. vannamei), and yellowtail (Seriola quinqueradiata). However, these compounds have all been administered as high-purity compounds, which might not necessarily have similar effects when they are in a matrix with other compounds.

Thus, it was considered whether the dietary inclusion of shrimp-derived products would affect health performance indicators in aquaculture species. Numerous performance indicators have been investigated in different studies. Based on the limited number of studies, it seems that the dietary inclusion of shrimp-derived products did not affect investigated health performance indicators. Interestingly, one study found that the dietary inclusion of shrimp meal resulted in an activation of the innate immune system. When African catfish (Clarias lazera) were fed a diet containing shrimp meal, there was an increase in both phagocytic activity and phagocytic index in heterophils compared to those fed a diet containing soybean meal. The increased activity of these immune system parameters could be related to the bioactive components described above. However, to further investigate this, more in-depth studies are required to identify the effects of shrimp-derived products on health performance and the contribution of the different bioactive components.

5 Current Challenges and Recommendations

The incorporation of shrimp-derived products into aquafeed presents several challenges that must be carefully addressed to ensure the production of safe and high-quality feed. These challenges encompass nutritional, economic, and quality, and safety aspects. In this section, the different challenges are addressed and potential strategies to overcome them are proposed.

5.1 Nutritional Challenges

Several nutritional constraints, such as the presence of chitin and high ash content, impede the use of shrimp meal and shrimp silage in aquafeed. Aquaculture research has indicated that dietary chitin can exert dual effects on aquatic animals. While low dietary inclusion levels can modulate immune functioning and gut microbiota composition, high dietary inclusion levels have been shown to negatively impair nutrient digestibility and growth performance. Feeding shrimp-derived products only to aquaculture species that are capable of digesting chitin will improve the utilization of these raw materials. Furthermore, separating shrimp solid processing waste into fractions of higher (head) and lower (abdominal exoskeleton and tail) nutritional quality, followed by their targeted use for different aquatic species, can improve raw material utilization without requiring additional processing. Further processing of shrimp-derived products to reduce chitin contents may be beneficial when high dietary inclusion levels are desired. Three main ways to reduce chitin in shrimp raw material are by chemical, mechanical, and biological treatments. Chemical treatments generally involve the use of acidic or alkaline solutions to break up the chitin structure. For example, a previous study treated shrimp meal with a 3% formic acid solution and found a reduction of 15% chitin on a DM basis. However, chemical treatment may also affect the physicochemical properties of other nutrients, such as amino acids, which could potentially decrease the nutritional quality of the raw material. Moreover, chemical treatment generates substantial volumes of chemical effluents that can, in some cases, be discharged into nearby water bodies, adversely affecting ecosystems. Mechanical treatment refers to the mechanical removal of chitin-containing fractions (head, abdominal exoskeleton, and tail) and is performed by methods such as meat/bone separation. Meat/bone separation has thus far shown to be only moderately successful in the removal of chitin from shrimp solid processing waste. For instance, a previous study was able to reduce the chitin content in shrimp heads by just 30% using meat/bone separation. On the contrary, biological treatments have been more successful in chitin removal, as they specifically target chitin and have relatively mild treatment conditions (i.e., temperature, pH, and pressure). To specifically target chitin, chitinolytic enzymes or chitinoclastic microbes are used to degrade chitin into more digestible compounds, such as chitin oligomers or glucosamine subunits. Studies using biological treatment have successfully converted up to 90% of chitin in shrimp solid processing waste into these compounds. For further research, it is recommended to focus on optimising biological methods to obtain the highest quality protein fraction with the lowest amount of chitin and ash, while also considering time and costs.

5.2 Economic Challenges

To make shrimp-derived products competitive to traditional protein sources, several economically related challenges must be addressed including market value and year-round availability.

5.3 Quality and Safety Challenges

The inclusion of shrimp-derived products in aquafeed poses certain quality and safety challenges. Spoilage is a primary concern, as shrimp solid processing waste is prone to rapid deterioration through various spoilage processes that have recently been extensively reviewed. These processes primarily include protein degradation, microbial degradation, and oxidation of proteins and lipids. Protein degradation occurs due to endogenous proteases originating from the head, muscle, and/or digestive tissues, which break down protein structures into, amongst others, free amino acids that can subsequently be used as a substrate for microbes. Microbial spoilage involves the activity of microbes present in the culture system or digestive tract, utilizing available nutrients and leading to the formation of volatile nitrogen compounds and biogenic amines, which pose safety concerns. Additionally, protein and lipid oxidation can occur, resulting in the formation of peroxides, which can decompose into various off-flavor compounds, decreasing the nutritional quality and potentially negatively affecting the palatability of aquafeed. To minimize spoilage, appropriate processing and storage conditions of shrimp solid processing waste are essential. Thermal treatment can be effective in denaturing certain proteases and providing a degree of sterilization, which can reduce enzymatic and bacterial degradation. Furthermore, maintaining suitable storage conditions, such as low temperatures and limited moisture, can help slow down spoilage processes. Implementing these measures systematically can aid in preserving the quality of shrimp processing waste and subsequent shrimp-derived products intended for aquafeed purposes.

6 Conclusions and Future Perspectives

This literature review described the nutritional composition, applications, challenges, and prospects of three shrimp-derived products (meal, hydrolysate, and silage) as alternative ingredients in aquaculture feed. Among these products, shrimp hydrolysate exhibited the highest nutritional value due to its high crude protein content, balanced amino acid profile, low chitin content, and low ash content. Despite having significantly higher ash and chitin contents, shrimp meal and shrimp silage still contain moderate to high levels of crude protein and a balanced amino acid profile.

The differences in nutritional value and the varying processing requirements affect their applications. Shrimp hydrolysate, with its superior nutritional value but intensive processing requirements, is most suited for carnivorous high-value aquaculture species such as Atlantic salmon (S. salar) and rainbow trout (O. mykiss). In contrast, shrimp meal and shrimp silage, which require less energy-intensive processing, are more appropriate for omnivorous lower-value aquaculture species that naturally consume feeds high in ash and chitin, such as common carp (C. carpio) and catfish (C. gariepinus).

Utilizing each shrimp-derived product for the appropriate aquaculture species already partially helps overcome some of the nutritional challenges related to their incorporation of aquafeed. Additionally, separating shrimp solid processing waste into higher (head) and lower (abdominal exoskeleton and tail) nutritional quality can aid in efficiently utilizing shrimp solid waste. Further processing techniques (chemical, mechanical, and biological) can be applied to reduce chitin and/or ash contents, improving their nutritional value. Advancing these processing techniques can also help reduce associated costs, making shrimp-derived products more competitive with currently used raw materials. One of the main quality and safety challenges is spoilage, which can be minimized through appropriate processing and storage conditions.

The prospects for using shrimp-derived products in aquaculture feed are promising, offering relatively high-quality aquafeed ingredients while simultaneously utilizing current shrimp solid waste streams.