STORAGE AND HANDLING TECHNIQUES FOR BETTER PRESERVATION OF AQUACULTURE FEEDS

Like any food products, aquaculture feeds need to be handled carefully and have a limited shelf life. These feeds must be handled and stored correctly to achieve their maximum nutritional and economic potential. By rotating the inventory often and making a concentrated effort to maintain good housekeeping and environmental conditions that deter mould growth and insect and rodent infestation, feed quality degradation during storage may be reduced. Aside from preventing nutrition loss, proper handling practises can help minimise pellet breaking right before feeding.

One cannot stress how crucial it is to pay close attention to the particular guidelines for handling and storing aquaculture feeds. Feed costs are typically the biggest single expense for farms that grow fish or prawns. As a result, even a tiny decrease in lost feed may have a big influence on production costs and profitability.

Introduction

Fish and prawns prepared feeds are perishable goods. Moreover, their fragility varies based on the kind of food. Feed processors work to improve the durability and shelf life of aquaculture feeds by formulating and manufacturing them. Ultimately, though, aqua culturists’ ability to minimise wasted feed and recover its entire purchase price hinges on how well they comprehend and implement the fundamentals of feed handling and storage.

Feed is typically the largest portion of the overall expense of rearing prawns and fish, and significant amounts may be lost to breaking and spoiling. Nevertheless, it can be challenging to locate specific information regarding the safe handling and storage of the most popular kinds of feed, and what is available is typically covered in passing in the literature. Generally, assumptions are made regarding handling protocols and specific storage conditions.

This article aims to give a thorough explanation of the most frequent reasons for the deterioration and waste of aquaculture feed on farms, along with informational references when appropriate. It is not practicable to cover every scenario that could arise during the processing and storage of any given feed type. That being said, in situations where decisions or concessions must be made, the rules and helpful suggestions provided below should be helpful.

Storage

Currently, dry diets are the most often utilised feeds in aquaculture due to affordability and simplicity. These consist of flakes, crumbles, hard pellets, and extruded feeds. Generally speaking, the best way to preserve these feeds is to keep them somewhere dry, well-ventilated, and somewhat protected from sudden temperature changes. Although minimising drastic swings is more important than determining the actual ambient temperature, cooler temperatures are preferable. Enough containment for pest management should also be provided by a quality storage facility.

Once feed has been delivered to the farm, little to nothing can be done to improve its potential storage stability, regardless of the type used. However, a lot of the subsequent actions taken during storage can significantly impact whether or not a feed can be tolerated for the duration of the planned shelf life. A practical understanding of the key elements that lead to feed degradation, along with some attention to maintaining appropriate storage conditions, can greatly reduce rancidity, mould growth, vitamin potency loss, and insect and rodent infestation.

Vitamin Potency

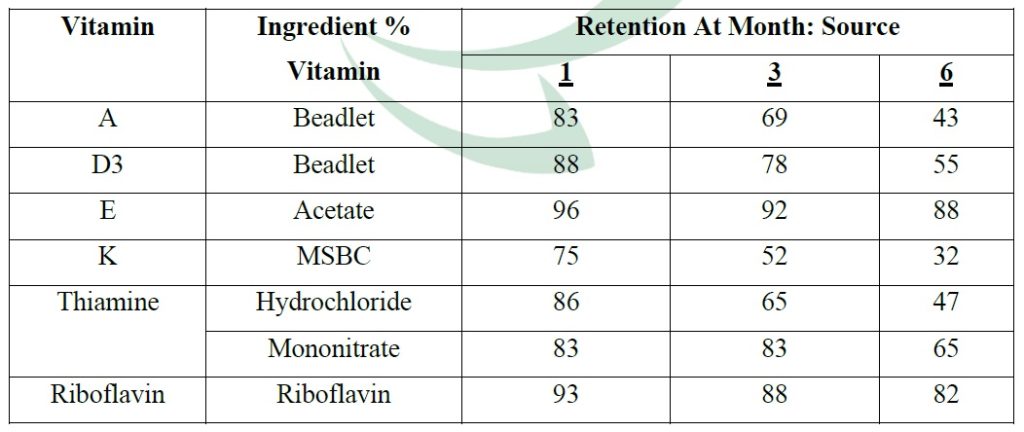

Most vitamins in formulated feeds lose some of their potency over time. This is a result of the high reactivity and instability of many of these organic compounds. Heat, oxygen, moisture, and even UV light can readily denature them in specific situations (2). The specific vitamin, its source, and the storage conditions of the feed all affect how quickly vitamin activity in a given feed formulation depletes. Table 1 summarises the average storage stability values of various vitamins and vitamin sources in dry feeds. Under suitable storage conditions, these data can be used to estimate normal vitamin activity losses (3,4). The majority of aquaculture feed producers are aware of these possible losses. They try to add enough excess of each vitamin to their diets to provide the desired levels of activity within the stated product shelf life.

Research has been done on the typical changes in vitamin activity levels that take place in fish feeds during extended storage (5). The findings demonstrated that vitamin levels in carefully planned diets could either meet or surpass the National Research Council’s (NRC) recommendations for Pacific salmon after three months if stored under the right conditions. Only vitamin C activity decreased below minimum acceptable levels after doubling the recommended storage time, according to additional monitoring of vitamin activity losses in these feeds.

It’s crucial to understand that feed does not necessarily need to become unusable due to substantial vitamin activity losses during storage. Rather than being determined by a particular concentration in the feed, vitamin requirements are actually a function of feed consumption and the desired biological response of the fish (6). Feed kept in storage for an extended length of time can still be beneficially used as long as the only deterioration occurring from storage is vitamin loss; this means that other quality issues like mould growth or fat rancidity are absent. Low vitamin activity feed can be used, for example, for a short time to feed fish that are ready for harvest or for a longer period of time to feed prawns or fish that are raised in conditions that require intensive culture. On the other hand, these feeds shouldn’t be utilised in situations where heightened vitamin activity is necessary to support an adaptive response, like illness resistance, or to attain the maximum amount of tissue storage, as needed in broodstock feed.

Table 1. Average Vitamin Stability in Stored Feeds

1 MSBC = Menadione Sodium Bisulfite Complex

2 MPB = Menadione Dimethyl Pyrimidinol Bisulfate

Mold Growth

Common moulds ruin feed that is kept in fish hatcheries and farms far too frequently. Due to the fact that various microbes and fungi that produce mould are naturally prevalent throughout the environment, there is always a chance that this will happen. They are found in grains that have been harvested and in animal corpses that have not been rendered. Activities involved in food processing heat and dehydration processes are commonly used in feed manufacture and stabilisation processes, which are effective enough to eradicate the contaminating microorganisms. Some fungi spores, meanwhile, may withstand challenging processing conditions. During handling and storage, feed may potentially get contaminated by additional airborne spores. All of these spores then wait for ideal growing circumstances to occur before going dormant within and on the meal.

The ideal conditions for contaminating fungus to develop are 14.5–20% moisture content in the feed and a relative humidity of 70–90% (7). Due to the significantly lower moisture levels used in the manufacturing process, extruded and pelleted feeds have a safety margin for variation in individual feed particles. For pet foods that are extruded, a maximum moisture level of 12% is advised (8). The majority of producers of aquaculture feed go one step further and maintain moisture levels at or below 10%. This is typically done because fish feeds have a propensity to be kept for extended periods of time, and low moisture pellets in bulk bins offer better handling qualities.

To further limit the likelihood of mould formation, certain additives can be employed that lower water activity and prevent fungal spores from germinating inside the feed. Many of these additions are really pricey, too. Speciality diets, such as semi-moist feeds, which have moisture levels of 14 to 20% but don’t require different storage conditions than dry feed, are often where cost-effective application is found.

Fungi spores in feed cannot be economically removed on a big manufacturing scale. Therefore, keeping the moisture content of stored feed below what is necessary for fungal development is the most efficient way to avoid mould formation. It goes without saying that providing a dry place where feed may be shielded from rain is required to do this. Controlling moisture movement inside the feed is more important than it seems. Even feed with 10% 6 average moistures can concentrate at substantially greater levels in the colder sections of a sack or bulk bin when there are enough temperature differentials.

Large amounts of feed cannot normally be stored in climate-controlled facilities. On the other hand, every attempt should be taken to prevent circumstances that permit abrupt and severe temperature swings. When bulk feed is kept in dark, poorly ventilated bins or bagged feed is kept outside under tarpaulins, moisture in the feed may volatilize during the day and condense near the top and surrounding surfaces of the containers as the temperature drops sharply at dusk. comparable wetness Even stacking feed bags at room temperature up against cold concrete walls and floors might cause migration. It’s just a matter of time until feed exposed to these types of storage conditions leads to the development of mould in isolated regions with high moisture content.

Aspergillus glaucus is often the first species of fungus to grow in feed, with a minimum moisture requirement of only 14.5% (7). Fish may often be fed feed with trace levels of pellets with this form of mould if it is discovered early on and there is little chance of negative outcomes. But as time goes on, the number of mould colonies grows swiftly, leading to conditions with increasing moisture and temperature. Other species immediately emerge and multiply as a result of the series of changes in the feed’s environmental circumstances brought about by the expansion of these spoiling bacteria. It is possible for A. flavus to infest moulding feed when the moisture content approaches 18% (7). Because it may produce aflatoxins, this particular form of mould poses a particularly serious risk. These carcinogenic compounds especially affect rainbow trout (9, 10). Aflatoxin B1 consumption of just 0.5 mg per kg of body weight results in death in 3–10 days. Hepatomas develop after four to six months of feeding feed infected with aflatoxin B1, even at concentrations as low as 0.1 to 0.5 ppb. While they are also harmed, some aquatic species including Coho salmon (9), catfish (11) and prawns (12, 13, 14, 14) are thought to be more resilient.

In actuality, there is very little chance that full meal will produce aflatoxin. Corn, cottonseed, peanuts, and other high-moisture crops have a far higher chance of experiencing it. Research has indicated that the existence of additional microorganisms in a complex substrate, such as fish feed, tends to hinder the synthesis of aflatoxin (7). However, some species of Penicillium and Fusarium fungus can also manufacture their own mycotoxins among these interfering microbes. This is why it is best to refrain from using feed that is visibly moulded.

Lipid Rancidity

The majority of fish and prawn species depend on unsaturated fatty acids for development and good health, hence these lipids are typically employed in aquaculture diets. Because of their high degree of unsaturation, these fatty acids are especially vulnerable to oxidative rancidity. Manufacturers of feed make an effort to stabilise lipid sources like fish oil with antioxidants to stop oxidation. However, the method that popular antioxidants like ethoxyquin, butylated hydroxy anasole, and butylated hydroxy toluene preserve the oil is sacrificial. After they are consumed, unsaturated fatty acid components in the oil react with free radicals already present, initiating the oxidation process.

Freezing is often regarded as the greatest long-term preservation technique. Cold temperatures, such as those attained by most freezers, do not, however, effectively slow down the pace at which free radicals develop or the ensuing lipid oxidation. In fact, freezing has been seen to promote lipid oxidation in low moisture diets (15). This is thought to be because, at standard freezer temperatures, only free water freezes. This leads to an unfrozen phase concentration of metal salts and other pro-oxidants, increasing the likelihood of interacting with lipids. It is also believed that oxygen might enter the pellets more easily because to the additional decrease in water activity brought on by freezing dry feed. All of this indicates that very little can be done on the farm to increase the stability of lipids in feed that has been stored. To prevent feed from being rancid before it is consumed, the only practical solution is to rotate the inventory of feed as soon as possible. Feeds that are provided in large quantities make this task simple. On the other hand, managing stocks of crumbles, starting meals, and broodstock pellets is typically more challenging. Additionally, animals who consume these feeds are probably in a stage of life where they are particularly susceptible to the harmful consequences of eating rancid lipids.

Pest Infestation

In aquaculture, the existence of rodents and insects in feed storage places is a significant issue that is sometimes disregarded. In addition to eating feed, these pests can also result in extra, even higher feed losses due to damage to packing and the establishment of mold-growing storage environments. They could also act as carriers of diseases that people can get from them.

Insects

When feeds are kept in storage for an extended length of time, insect infestation can become a very significant issue. The amount of feed loss that insects may cause is sometimes minimised by jokes about how they “just add a little protein to the feed.” A colony of insects that is actively reproducing can quickly eat large amounts of food and degrade the physical quality of the feed that is still available (16). Grain weevils and warehouse beetles are examples of internal infesting species that may pierce feed bags, opening a point of entrance for other insects. Furthermore, they have the ability to cause localised heating, moisture migration, and moulding if they are present in large enough quantities in bulk feed. However, issues with full feeding are most often caused by external infesting organisms. Among them are Indian meal moths and flour beetles, which prefer to obtain nourishment from processed grain products, along with carpet beetles that feed on meat meal, feather meal and other ingredients of animal origin.

The majority of these insects do well on diets with 12–14% moisture content. When temperatures are between 20 to 30°C, they may fully grow from an egg to a reproductively active adult in about 30 days. The majority of these species stop laying eggs at 16°C. It is normally at 4.5°C when they go dormant. Due to their relatively high fertility and short maturation time, insects may reproduce in enormous numbers under ideal climatic circumstances extremely quickly.

It is simple to see that successful control necessitates a persistent and coordinated effort on many preventative and housekeeping duties given the knowledge and capacity to recognise situations that favour insect infestation and rapid population increase. The most crucial control procedure is perhaps the quick rotation of inventories. On the other hand, proactive measures like routine feed inspection, early insect identification, and proper hygiene in storage facilities can significantly lower the likelihood of bug contamination in feed. Insecticides are a last resort for getting rid of a chronic infestation.

According to Environmental Protection Agency (EPA) standards, all chemicals used as insecticides in the US must be properly marked and registered for that application. Applying fumigants like methyl bromide, hydrogen phosphide (also known as phosphine gas), and 10 chlorpyrifos-methyl necessitates the certification of personnel from overseeing state authorities. These pesticides don’t leave any residue in the feed and work really well. The vapours are quite poisonous, though. When treating feed, fumigant pesticides should only be used very sparingly and in accordance with the manufacturer’s instructions.

Rodents

It goes without saying that established populations of rats and mice in storage spaces eat some feed. But the losses they bring about by breaking down the container, spilling the feed, and exposing the food to mould and insects are probably far higher. Additionally, they represent a serious health risk to the employees handling the feed.

Similar to insect pests, successful management requires the coordinated application of many treatments. Good housekeeping, both within the warehouse and on the outside, should always be the cornerstone of any rodent control programme. When combined with vigorous trapping efforts and the upkeep of physical barriers that restrict entrance, feed losses from rats can be significantly reduced.

When it comes to managing rat populations in feed storage facilities, the use of poisons should only be a last choice. When baits containing acute rodenticides, such as strychnine, are placed near feed that has been kept, there is a greater chance of feed contamination and potentially harmful human or pet contact. Even though they are significantly less hazardous, anticoagulant rodenticides like warfarin have the same hazards.

Handling

On a farm, moving feed must only be viewed as a necessary evil. Every time feed is handled throughout the receiving, storage, and feeding procedures, some feed or nutrients are lost. These long-term losses are typically negligible, but they add up over time. Identifying the main sources of loss and making any required practical adjustments to handle feed as little as possible and gently are acceptable general control strategies. Dry feeds that are extruded or pelleted both offer superior handling qualities. For both varieties of dry feed, pellet durability is often rather excellent. However, certain batches of feed may be softer and more brittle because to variations in the consistency of the components. Feed makers use components with strong binding qualities and add feed additives to assist raise the hardness of the pellets in order to lessen the occurrence of soft feed. Pellets’ spherical or cylindrical particle shapes further lessen breakage and facilitate the easy flow of dry feed from trucks, bins, and feeders.

Inherent restrictions are frequently contested since the physical properties of dry feeds are so well suited to the handling and distribution requirements of aquaculture. It is easy to forget that crumbles and pellets, no matter how resilient, can decompose into dust and particles when enough compression and abrasion is applied. It’s critical to pay careful thought to adjusting the feed as little and gently as feasible.

Reducing the amount of particle size attrition that happens when pellets or crumbles are forced to rub against one another is a difficulty when using bagged feed. It is possible to handle bags in numerous units by using hand trucks and mini-pallets or forklifts and pallets. By doing this, less feed is moved within each bag, which lowers the quantity of dust and particles produced. Single bags may need to be handled, but care must be used during the procedure. It goes without saying that harsh treatment, such stepping on feed bags or hurling them, should be avoided.

Controlling pellet-against-pellet abrasion in bulk feed is more challenging. Pellets must go from the delivery vehicle to a bin and then from the bin across the farm due to the very nature of this technique of handling and storing feed. Additionally, it demands the utilisation of conveying machinery. The majority of issues with high dust and fine levels in bulk feed are frequently caused by or resolved by these mechanical devices Bucket elevators, drag conveyors and belt conveyors are the least damaging forms of feed conveying machinery that are often utilised (17). These are effective because they minimise the possibility of pellets being sheared or pinched in conveying systems and regulate feed against feed movement. Conveyors that are pneumatic, oscillating, or vibratory only marginally increase abrasion. However, when correctly maintained and operated, they almost minimise losses due to pellet breakage.

The auger is the feed transportation mechanism with the highest risk for damage. Due to their low cost and ease of use, farms frequently utilise both flexible augers and tube type screw conveyors in their feed handling systems. The most common application for them is in bulk bin unloading. In this case, the auger’s high-speed rotation and angled discharge make the equipment design more suitable for processing mash feeds or whole grain. Additionally, the majority are “choke-loaded,” which means that feed completely encloses the conveyor’s entrance, compressing and shattering the pellets as they enter the tube. Although many of these issues may be avoided with correct equipment design, the additional cost typically favours the adoption of conveyors that are more appropriate for use with feed.