AQUACULTURE FEEDERS AND THEIR STRATEGIC IMPLEMENTATION

Automatic feeders are transforming aquaculture by allowing for precise feeding regimens that enhance growth and reduce feed waste. Demand feeders offer tailored feeding based on fish appetites and can operate without electricity. This review examines the evolution and technological advancements of these feeders, including a survey of recent research. It evaluates various feeder designs and compares five automatic configurations currently used in commercial settings. The article also contrasts feeder types and feed sizes for different farmed species across various life stages and facilities. It emphasizes the significance of species-specific feeding strategies and their effects on fish behavior, health, nutrient delivery, and environmental sustainability. The integration of sensors and computing technologies is highlighted for optimizing feeding algorithms. Additionally, the review compiles studies comparing growth rates and feed conversion ratios between automatic and demand feeders versus traditional hand-feeding methods. Finally, it discusses the integration of real-time monitoring and data analytics, pointing to future research directions and industry adoption.

1. Introduction

The aquaculture industry has a rich history of utilizing modern technologies to enhance the controlled cultivation of seafood. This document explores the evolution of aquaculture practices, highlighting the integration of innovative techniques that have emerged to meet the growing global demand for seafood while reducing pressure on wild fish stocks. From its ancient origins to its current sophisticated state, aquaculture has transformed into a vital sector for food security and sustainability.

Aquaculture’s roots can be traced back to ancient civilizations in Asia, Africa, and Europe, with early practices such as pond-based carp farming in Neolithic China. Over time, the industry diversified, adopting species-specific technologies, such as tilapia farming in Egypt and oyster cultivation in the Roman Empire. In recent decades, advancements like automatic feeders and recirculating aquaculture systems (RAS) have revolutionized production methods, enhancing efficiency and addressing environmental concerns.

The farmed seafood market has experienced steady growth, driven by increasing consumption and declining wild fisheries. Governments worldwide are recognizing the potential of aquaculture, with various countries implementing supportive policies and subsidies. For instance, the United States has prioritized aquaculture since the National Aquaculture Act of 1980, reflecting the sector’s importance in meeting fish supply demands.

Technological innovations, particularly automatic feeders, have played a crucial role in the industry’s expansion. These feeders improve feed management, reduce waste, and lower labor costs, leading to better feed conversion ratios and nutrient utilization. By automating feeding processes, aquaculture operations can achieve more consistent and efficient feeding schedules, mitigating risks associated with manual feeding.

Advancements in genetics and biotechnology are also enhancing aquaculture practices through selective breeding and improved hatchery techniques. These developments have resulted in genetically superior strains that exhibit better growth rates and disease resistance. Automatic feeders complement these advancements by allowing for precise adjustments in feeding, catering to the needs of these enhanced species.

Environmental sustainability is a growing focus within aquaculture, with innovations like integrated multi-trophic aquaculture (IMTA) systems exemplifying efforts to minimize ecological impact. By combining fish farming with seaweed or bivalve cultivation, IMTA systems recycle nutrients and reduce waste, showcasing the industry’s commitment to sustainable practices.

As aquaculture continues to grow, the demand for efficient and sustainable feeding technologies remains paramount. Automatic feeders have emerged as essential tools for achieving these goals, enabling precise control over feeding schedules and reducing environmental impacts. This article reviews the evolution of feeding technologies in aquaculture, examining the applications of automatic feeding systems and their contributions to productivity, sustainability, and economic viability.

This review synthesizes current knowledge and research on feeders in aquaculture, providing insights into the benefits and challenges of various feeding regimes. By presenting quantitative results from multiple studies, the document aims to inform aquaculture practitioners about the potential advantages of adopting automatic feeders in their operations.

2. Background

Aquaculture is an expanding global industry crucial for food security, valued at $204 billion in 2020, with a projected growth rate of 3.6% from 2021 to 2026. Efficient feeding solutions are vital for profitability and environmental sustainability, leading to the adoption of automatic feeders that enhance feed distribution and reduce labor costs. Historical advancements in fish cultivation have paved the way for modern feeding systems, evolving from simple timers to sophisticated setups with sensors and programmable logic controllers. These innovations improve performance under diverse conditions and increase the accuracy of fish detection technologies. Tailored feeding strategies have shown to optimize growth rates and feed efficiency for various aquatic species. The implementation of continuous versus intermittent feeding schedules influences fish behavior and nutrient absorption. Sustainability is a growing concern, with automatic feeders helping to minimize feed waste and improve water quality. Integration with environmental monitoring systems further enhances feeding efficiency by adjusting schedules based on real-time data. Overall, technological advancements in automatic feeders have significantly improved aquaculture practices, promoting resource optimization and reducing environmental impacts.

3. METHODS

Automatic feeding systems have evolved significantly since their inception, driven by technological innovations and scientific advancements. An early design by David C. Smeltzer used an adjustable counterbalance weight to dispense feed from a pan (Uddin et al., 2016). This laid the groundwork for a wide variety of designs for automated feed delivery systems in aquaculture. Demand-based feeders have largely been overtaken by automatic feeders in recent years (Váradi, 1984). However, modern demand feeders that digitally measure proxies for appetite (e.g., using acoustic sensors or motion tracking) are increasingly seeing adoption (Jescovitch et al., 2018; Reis et al., 2020; Ullman, Rhodes, Hanson, et al., 2019).

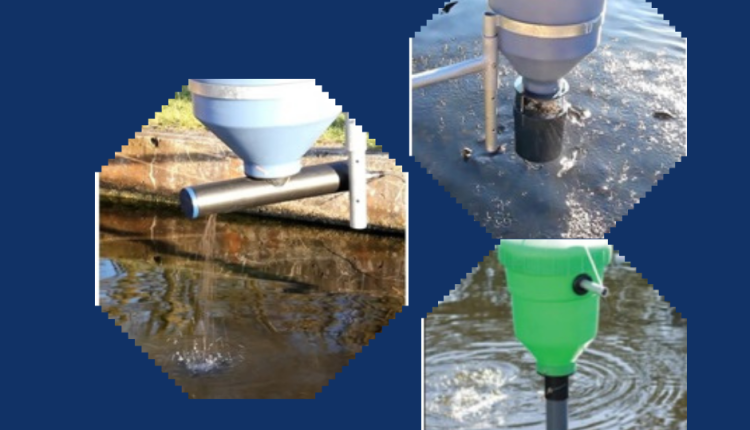

3. 1. Demand Feeders

Demand feeders are innovative solutions for aquaculture operations lacking on-site power, dispensing feed based on the activity of farmed species. They are categorized into two types: bait-rod (or pendulum-type) feeders and submerged-plate feeders. Bait-rod feeders feature a rigid rod that fish can agitate to release a fixed quantity of feed, promoting a learned behavior in hungry fish. However, this design is less effective for young fish that cannot trigger the mechanism. Pendulum-type feeders also help measure fish appetites and feeding behavior, as observed in a study with European sea bass, where dominant individuals actuate the feeder for the group. Conversely, submerged-plate feeders release feed when fish consume all from a plate, making them suitable for smaller fish. Despite their benefits, both feeder types risk overfeeding due to overly sensitive triggers or unintended activations, prompting a shift towards automatic feeders for better control and monitoring in the industry.

3. 2. Automatic Feeders

Automatic feeders have revolutionized aquaculture by enhancing feed accuracy, minimizing waste, and optimizing feed conversion ratios (FCRs) compared to manual demand feeders. Technological advancements have led to the development of various automatic feeder designs, primarily powered by electric, pneumatic, or hydraulic energy sources. Some feeders, like Hawaii-type dispensers, operate without electrical connections, while solar photovoltaic (PV) panels are increasingly used for off-grid installations, particularly in rural areas of Sub-Saharan Africa.

The most common automatic feeders consist of a hopper, a motor-driven doser or screw auger, and a thrower fan/propeller that disperses feed into the water. Feed is loaded into the hopper and, through gravity, is dispensed at controlled rates into the water. Variants exist, such as those without a thrower motor, which rely solely on gravity for feed distribution. These are referred to as auger-only automatic feeders, while the more prevalent design is known as spread/throw automatic feeders. A comparative analysis of these feeder types highlights their operational differences and efficiencies in aquaculture settings.

3.3. Feeder configurations and applications

The choice of feeder size and type is influenced by factors such as the type of enclosures (ponds, nets, or RAS tanks) and the specific needs of the fish being raised.

The five major automatic feeder configurations include the single feeder, which is the most common, featuring a hopper and doser. Moving feeders are truck-mounted systems that automate feeding while being manually driven between enclosures. Rail feeders operate on a fixed rail system, allowing multiple feeder modules to distribute feed. Drag chain feeders utilize a tube-based system to transport feed to enclosures, while central feeders use a central silo to distribute feed through various systems.

Research by M. Tanveer et al. emphasizes the importance of adapting feeding strategies for fish of different ages and sizes, which is crucial for selecting the appropriate feeder type. The document also discusses the use of live feed for certain fish species, particularly altricial larvae, which cannot digest formulated feeds immediately after hatching. In contrast, precocial species are capable of consuming dry feed right away due to their more developed digestive systems.

4. ADVANCES IN FEEDERS

The first automatic feeders for aquaculture released feed based on fixed schedules using electrical or mechanical timers. Recent advancements in feeders have focused on enhancing reliability, accuracy, and efficiency in feed delivery. Many modern automatic feeders incorporate sensors, actuators, and PLCs to enable adaptive feeding strategies based on fish age and size as well as real-time fish behavior and environmental conditions. Ullman et al. document how fish behavior is sensed or tracked autonomously to measure fish appetite and dispense aquafeed accordingly with automatic feeders (Ullman, Rhodes, & Allen Davis, 2019; Ullman, Rhodes, Hanson, et al., 2019).

4.1. Adjusting feeding regimes

Feeding strategies vary according to species and aquaculture settings. Le Boucher et al. (2023) introduce feed optimization algorithms that utilize real-time sensor data to dynamically adjust feeding rates based on fish size, age, and appetite. Their methods—stepwise regression, Bayesian model averaging, and multiple factorial polynomial—enhance feed efficiency and growth rates. Automated feeding systems influence fish behavior and intake patterns, allowing precise control over feeding schedules. Paspatis and Boujard (1996) highlight the role of these systems in optimizing salmonid feeding behavior, resulting in more uniform growth. Factors like hunger, stress, lighting, temperature, and water chemistry affect feeding behavior, which can be monitored by advanced sensors. Zhang et al. (2023) demonstrate that these sensors help reduce competition for feed and stress among farmed fish. Azzaydi et al. (2000) further show that programming feeders to align with natural feeding rhythms promotes healthy growth and minimizes environmental impact. Overall, automatic feeders significantly enhance aquaculture operations by maximizing growth and improving animal welfare.

4.2. Sustainability and environmental measures

The sustainability of aquaculture is increasingly reliant on effective resource management and environmental stewardship. Automatic feeders play a significant role in reducing feed conversion ratios (FCRs) and feed waste, which helps mitigate the adverse environmental effects of nutrient discharge and ecosystem degradation. Uneaten feed contributes to organic matter in water, leading to nutrient enrichment that harms aquatic ecosystems. Global assessments of feed-food competition in aquaculture utilize natural trophic levels and human-edible protein conversion ratios to minimize aquafeed waste. Sustainable feed formulations are being developed, incorporating alternatives like soybean and insect larvae, reducing reliance on marine resources. The size of feed is crucial for automatic feeders, which are designed for specific feed sizes. Integrating automatic feeders with environmental monitoring systems enhances aquaculture management, allowing real-time data collection on water quality. This integration supports adaptive feeding strategies and helps maintain optimal conditions for fish health. Effective nutrient management strategies are essential for reducing water pollution and the ecological footprint of aquaculture operations.

5. RESULTS: COMPARING FEEDERS AND FEED DISTRIBUTION SCHEMES

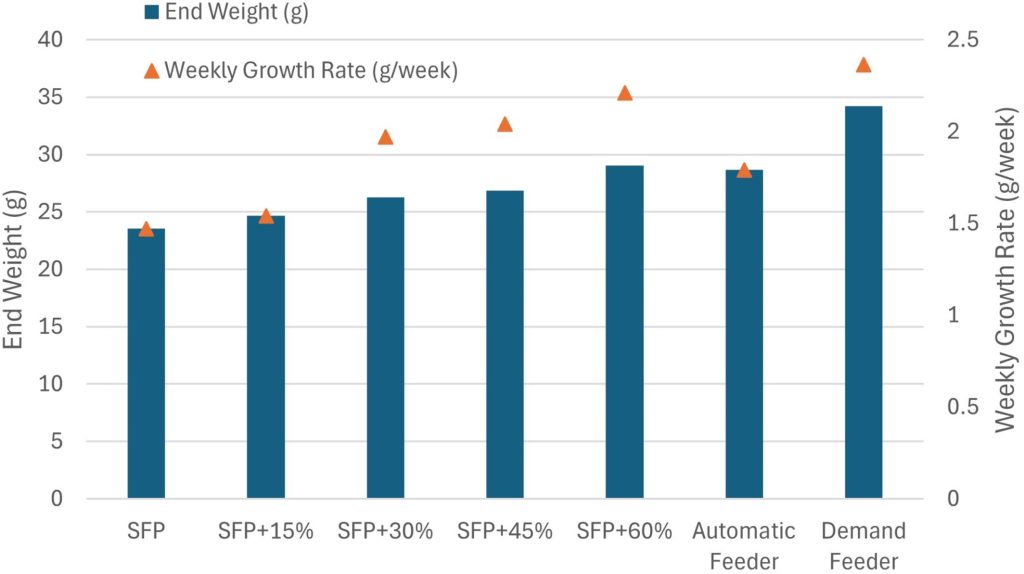

The timing of feed distribution is crucial for delivering accurate nutrients, thereby optimizing growth and nutritional quality in aquaculture. Different species cultivated in the industry have unique feeding behaviors and nutritional needs, necessitating customized feeding regimes. Automatic feeders can be tailored to these specific requirements, resulting in high growth rates and reduced food waste. Demand feeders have emerged as a promising alternative, showing superior growth outcomes in recent studies. Studies on the shrimp species Litopenaeus vannamei reveal that demand feeding outperforms traditional hand feeding methods in terms of weight gain and growth rates. While results are specific to this shrimp species, optimal feeding strategies vary across species and require adjustments based on age and size. Ensuring the right nutrient blend is essential for the health and growth of farmed species. For instance, lipid composition in krill-based feeds is critical for different trout and salmon species, while balanced diets for oysters aim to meet nutritional needs with minimal environmental impact.

Fig : Weekly growth rates and end weights resulting from different feeding regimes and feeder options for pond-cultured shrimp (Litopenaeus vannamei) (Jescovitch et al., 2018; Reis et al., 2020; Ullman, Rhodes, Hanson, et al., 2019).

6. Discussion

Automatic feeders are primed for research aimed at boosting efficiency and sustainability. Advanced technologies, such as digital sensors, are crucial for precise feed distribution and real-time monitoring of fish behavior (Van Riel et al., 2023). These sensors allow for adjustments in feeding schedules based on environmental conditions, maximizing feed efficiency and minimizing waste. For instance, acoustic sensors enable real-time feeding based on fish behavior, improving production in shrimp farming (Ullman et al., 2019). The Internet of Things (IoT) enhances remote monitoring and data transmission, vital for operational oversight (Arepalli & Naik, 2024). Future developments will incorporate AI and machine learning for adaptive feeding strategies (Hu et al., 2022).

Efficient operation and maintenance of feeders are critical for their longevity. Training programs for aquaculture personnel on feeder management and regular maintenance schedules are essential for reliable performance (Myers, 2021). Data analytics plays a key role in optimizing feed management, providing insights into feeding rates and fish growth, which can refine feeding protocols (Zhang et al., 2023).

Adhering to regulatory standards and promoting sustainable practices are fundamental for responsible aquaculture. Compliance with local regulations and sustainable feed management practices is essential for environmental stewardship (Shipton & Hecht, 2013). Continued investment in research and collaboration among stakeholders is vital for innovation in feeder technology, addressing challenges like reliability and optimal feed formulations. Embracing emerging technologies will enhance feeder performance and expand their use in diverse aquaculture environments, ultimately supporting global seafood demands while protecting aquatic ecosystems.

7. Conclusion

Automatic feeders are becoming crucial for scaling modern aquaculture and enhancing profitability. They offer precision, efficiency, and sustainability, leading to higher weight gains compared to traditional hand feeding. Studies indicate that demand-based feeding, which adjusts to the appetite of the fish or crustaceans, yields even better growth rates and final weights than timed automatic feeders. This information is vital for farmers as they choose feeders for their operations. By leveraging technological advancements and data science, these feeders improve production without sacrificing efficiency or environmental responsibility. The adoption of mechanized feeders presents a transformative opportunity for sustainability and profitability in aquaculture. Tailoring feeds and regimens to specific species will enhance aquaculture production while reducing seafood costs, ultimately addressing food scarcity and providing affordable protein. Emphasizing environmental stewardship and operational reliability, ongoing research and collaboration are key to maximizing the benefits of automatic feeders in meeting global seafood demands while protecting marine ecosystems.

Source : Thornburg, J. (2025). Feed the fish: A review of aquaculture feeders and theirstrategic implementation. Journal of the World Aquaculture Society, 56(2), e70016. https://doi.org/10.1111/jwas.70016.